optacom contour: functional overview

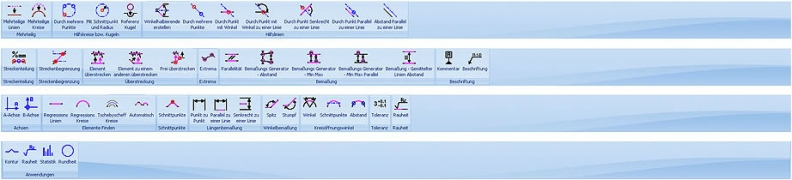

- Semi-automatic search of all elements with a single mouse-click

- Manual or automatic element adjustment and optimization

- Evaluation of radii, distances and angles

- Creation of intersection points between any elements

- Regression lines or regression circles

- Regression adjustment with specified Gaussian or Chebyshev circles

- Multi-part regression lines or regression circles

- Fitting of test balls with a given radius and a definable direction angle

- Auxiliary lines: Parallel, perpendicular, straight lines with definable angle and distance

- Auxiliary circles: Through several points at intersections with given diameter

- Auxiliary points: Coordinate points, contour points, contour intersections, etc.

- Finding the highest / lowest point of contours and elements with respect to a reference

- Numeric and graphical determination of form deviations on lines and circles

- Numerical and graphical straightness and profile depth of lines

- Circular opening angle for regression circles

- Ordinate guideline for regression circle and regression line

- Automatic dimensioning with tolerance assessment for repeat measurements

- Zoom from 1:1 to 5000:1 for the evaluation, independent from printing

- Comments and texts

- Export function to Q-DAS

- Export function to Excel

- Newly developed printing functions with various output options

- Multi-contour printout supports multiple contours on a sheet

- Flexible representation of your company data, company logo, part numbers, etc.

- Segmented measurements in the entire measuring range without loss of reference

- Stylus tips compensation for all stylus directions

- Fully automatic calibration of stylus tips

- Newly developed tools for evaluating ball screws

- DXF import and sheet comparison

- Reference part database Q-DAS compatible

- All reports can display the reference system

- Extensive element list displays all element details

- Part comparison can also be done with modified measurement conditions or lengths

- Simple red-green evaluation with tolerances